-

GZY-D840

4Ports UHF RFID Reader4-Port RFID Split-Type Reader for Industrial-Grade Reliability, Lightning-Fast Identification, and Dual-Protocol CompatibilityView Details -

GZY-E609

High-Performance RFID Integrated ReaderUltra-high frequency integrated reader series, high-performance RFID integrated reader, all-weather operation, stable long-distance reading, applicable to access control, logistics and other applications.View Details -

GZY-33

USB Tablet Desktop RFID ReaderSpecialized RFID reading and writing station for physical evidence, with a 400mm large surface and adjustable power of 33dBm.View Details -

GZY-T509

9dbi RFID Circularly Polarized AntennaRFID ultra-high frequency 9dBi antenna, with strong anti-aging and weather resistance, capable of stable operation in harsh environments.View Details -

GZY-202

UHF RFID Handheld RederRFID handheld terminal reader, with high processing performance, long tag reading distance and high group reading rate, is widely used in logistics, asset management and other scenarios.View Details -

GZY-122

1-2M Android RFID Handheld RederRFID handheld terminal reader, with high processing performance, Multifunctional RFID warehouse inventory handheld device, integrating RFID and biometric identification,with excellent performance and stability.View Details -

GZY-E98

8Port RFID Reader ModuleView Details -

GZY-R1808

Printable small anti-metal RFID labelRFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse managementView Details -

GZY-R6025

Custom anti-metal RFID labelRFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse managementView Details -

GZY-P8020

7m long distance uhf rfid tag7-meter ultra-long-range PCB anti-metal tags, with industrial-grade protection, an excellent tool for warehouse shelf managementView Details -

GZY-A13042

12m UHF Rugged RFID TagsView Details -

GZY-A20043

35m Long Distance RFID Hard Metal TagsView Details -

GZY-X5012

UHF RFID laundry tagView Details -

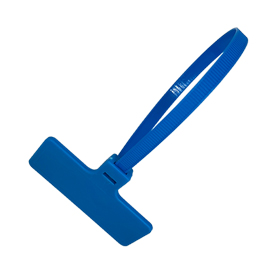

GZY-Z30

Plastic RFlD Tracking Seals TagRFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse managementView Details -

GZY-Z4028

RFID Anti-Theft Security Seals TagView Details

- Home

-

Power & Grid

-

Infowise RFID

Product Number

GZY-P8020

GZY-P8020

7-meter ultra-long-range PCB anti-metal tags, with industrial-grade protection, an excellent tool for warehouse shelf management

GZY-P2510

GZY-P2510

Ultra-thin anti-metal PCB tags, a powerful tool for managing metal equipment/tool assets

GZY-P0505

GZY-P0505

Micro anti-metal PCB tags, stable reading of items on metal surfaces, industrial-grade IP68 protection

GZY-P305

GZY-P305

GZY-P1207

GZY-P1207

High-performance PCB anti-metal electronic tags, stable reading for metal surface items

GZY-P1309

GZY-P1309

RFID asset management PCB tags, stable reading and writing in extreme environments, suitable for medical devices/asset management

GZY-P1616

GZY-P1616

RFID equipment manages electronic tags, with stable reading and writing performance in extreme environments, suitable for equipment/asset management.

GZY-P1809

GZY-P1809

RFID anti-metal electronic tag, UCODE 8 chip, IP68 protection, extreme temperature tolerance

GZY-P2208

GZY-P2208

Ultra-high frequency anti-metal PCB tag, metal surface 4.5 meters precise recognition, industrial-grade durable design

GZY-P2309

GZY-P2309

Industrial-grade PCB anti-metal tags, remaining functional in harsh environments

GZY-P3005

GZY-P3005

Ultra-thin anti-metal PCB tags, a powerful tool for managing metal equipment/tool assets

GZY-P3612

GZY-P3612

RFID mine personnel positioning tag, industrial-grade metal-resistant, suitable for harsh environments

GZY-P5010

GZY-P5010

PCB anti-metal RFID inspection tag, 5.5-meter mobile recognition, unaffected by oil stains and vibrations

GZY-P7020

GZY-P7020

Ultra-long-range 9-meter PCB anti-metal tag, with industrial-grade protection, suitable for large equipment/warehouse management

GZY-P9525

GZY-P9525

10.5-meter ultra-long-range PCB anti-metal tags, specially designed for industrial-grade heavy equipment management

GZY-P0904

GZY-P0904

PCB fixed asset electronic tags, stable reading of items on metal surfaces, IP68 protection suitable for harsh environments

GZY-P1005

GZY-P1005

Small-sized PCB anti-metal tag, IP68 protection, 50-year data retention

GZY-P1307

GZY-P1307

Tool management RFID anti-metal PCB tags, stable reading and writing in extreme environments, suitable for equipment/asset management

GZY-P1504

GZY-P1504

RFID anti-metal PCB passive electronic tag, stable reading and writing in extreme environments, suitable for equipment/asset management

GZY-P1806

GZY-P1806

PCB anti-metal RFID tags, stable reading and writing in extreme environments, suitable for devices/asset management

GZY-P305

GZY-P305

Locatable RFID anti-metal PCB tags with fast, accurate and stable reading/writing capabilities Product Number

Product NumberGZY-R1808

GZY-R1808

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-R6025

GZY-R6025

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-R3015

GZY-R3015

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-R3012

GZY-R3012

RFID flexible printable electronic tags, optimized for metal surface applications, compatible with non-metal surfaces

GZY-R4025

GZY-R4025

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-R5015

GZY-R5015

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-R5025

GZY-R5025

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-R6505

GZY-R6505

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-R6535

GZY-R6535

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-R7025

GZY-R7025

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-R7030

GZY-R7030

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-R8025

GZY-R8025

UHF flexible anti-metal tag, equipped with Impinj Monza R6/M730 chip, capable of 100,000 write-erase cycles,with 10-year data storage capacity

GZY-R8040

GZY-R8040

High and low temperature resistance flexible label, With a wide temperature range of -40°C to +120°C, IP68 protection against moisture and corrosion, suitable for harsh environments

GZY-R9522

GZY-R9522

Industrial-grade weather-resistant RHID flexible labels, with a reading distance of up to 5 meters on metal surfaces

GZY-R10040

GZY-R10040

Large-sized flexible RFID electronic tags, used in scenarios such as IT assets, automotive parts, and warehouse logistics management

GZY-R8020

GZY-R8020

9.5-meter ultra-long-range PCB anti-metal tags, with industrial-grade protection, an excellent tool for warehouse shelf management

GZY-R8050

GZY-R8050

无GZY-R5515

GZY-R5515

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management Product Number

Product NumberGZY-X5012

GZY-X5012

GZY-X1818

GZY-X1818

GZY-X2020

GZY-X2020

GZY-X2525

GZY-X2525

GZY-X5815

GZY-X5815

GZY-X7015

GZY-X7015

GZY-X7512

GZY-X7512

Ultra high-frequency RFID clothing labels that have withstood 200 industrial washes at 180°C, with anti-theft protection during sewing installation.

GZY-X8616

GZY-X8616

Product NumberGZY-A13042

GZY-A13042

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-A20043

GZY-A20043

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-A105

GZY-A105

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-A6923

GZY-A6923

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-A8724

GZY-A8724

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-A8520

GZY-A8520

Long-distance RFID anti-metal tag, 12 meters long range IP68 protection, -40°C corrosion-resistant with 100,000 times write erase cycles

GZY-A8724

GZY-A8724

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-A9525

GZY-A9525

RFID ultra-thin anti-metal tag, 12-meter long-range, IP68 protection, -40°C corrosion-resistant, 100,000 times write erase cycles Product NumberProduct Number

Product NumberProduct NumberGZY-Z30

GZY-Z30

RFID flexible anti-metal tags, with back adhesive application design, suitable for scenarios such as asset and warehouse management

GZY-Z4028

GZY-Z4028

GZY-C11045

GZY-C11045

GZY-C8554

GZY-C8554

GZY-M6617

GZY-M6617

GZY-S750

GZY-S750

GZY-LED PCB6020

GZY-LED PCB6020

GZY-S6025

GZY-S6025

GZY-A8654

GZY-A8654

GZY-Z3328

GZY-Z3328

GZY-Z1912

GZY-Z1912

GZY-Z3328

GZY-Z3328

GZY-Z5028

GZY-Z5028

GZY-Z7530

GZY-Z7530

GZY-Z6028

GZY-Z6028

GZY-Z8030

GZY-Z8030

GZY-C11045

GZY-C11045

Vehicle RFID self-adhesive label for 8-meter glass penetration, IP65 protection against extreme temperature changesProduct NumberGZY-D840

GZY-D840

4-port RFID split-type reader 700 tags/second high-speed inventory Military-grade components ensure 365 days of non-stop operation

GZY-D880

GZY-D880

8-port RFID split-type reader 700 tags/second high-speed inventory Military-grade components ensure 365 days of non-stop operation

GZY-D816

GZY-D816

16-port RFID split-type reader 1000 tags/second high-speed inventory Military-grade components ensure 365 days of non-stop operation Product Number

Product NumberGZY-E609

GZY-E609

Ultra-high frequency integrated reader series, high-performance RFID integrated reader, all-weather operation, stable long-distance reading, applicable to access control, logistics and other applications.

GZY-605

GZY-605

The ultra-high frequency integrated reader series is a high-performance, all-weather industrial-grade fixed 5dBi reader.

GZY-E612

GZY-E612

Ultra-high frequency integrated reader series, high-performance RFID integrated reader, all-weather operation, stable long-distance reading, applicable to access control, logistics and other applications.

GZY-608

GZY-608

Ultra-high frequency integrated reader series, industrial RFID high-speed reader, IP65 protection with a 10-meter long-range, multi-mode intelligent control for vehicle logistics

GZY-612

GZY-612

Ultra-high frequency integrated reader series, RFID industrial-grade passive identification all-in-one machine, water-resistant and durable, with stable long-distance performance, supporting multiple protocols, suitable for access control, logistics and other scenarios

GZY-610

GZY-610

Ultra-high frequency integrated reader series, industrial-grade RFID integrated reader, rugged and durable, multi-mode support, suitable for intelligent warehousing and manufacturing.

GZY-E606

GZY-E606

Ultra-high frequency integrated reader series, industrial-grade RFID integrated reader, rugged and durable, multi-mode support, suitable for intelligent warehousing and manufacturing.

GZY-E607

GZY-E607

Ultra-high frequency integrated reader series, high-performance RFID integrated reader, all-weather operation, stable long-distance reading, applicable to access control, logistics and other applications. Product Number

Product NumberGZY-33

GZY-33

Specialized RFID reading and writing station for physical evidence, with a 400mm large surface and adjustable power of 33dBm.

GZY-77

GZY-77

RFID Desktop Reader-Writer Series RFID Card Issuance Device, Intelligent, Efficient, Flexible Communication

GZY-76

GZY-76

Desktop RFID card issuing machine, intelligent automatic label input, portable and efficient

GZY-31

GZY-31

RHID tag reader, compact 255mm body, 50 tags per second precise near-field inventory

GZY-32

GZY-32

Near-field RFID reader, 370mm high-efficiency group reading,one-click output on the simulated keyboard

GZY-36

GZY-36

An RFID checkout counter with a 600mm large-sized countertop, capable of batch binding 50 tags per second, has an IP54 protection rating and is suitable for general use in various scenarios.

GZY-D4L

GZY-D4L

An RFID checkout counter with a 600mm large-sized countertop, capable of batch binding 50 tags per second, has an IP54 protection rating and is suitable for general use in various scenarios.Product NumberGZY-202

GZY-202

RFID handheld terminal reader, with high processing performance, long tag reading distance and high group reading rate, is widely used in logistics, asset management and other scenarios.

GZY-122

GZY-122

RFID handheld terminal reader, with high processing performance, Multifunctional RFID warehouse inventory handheld device, integrating RFID and biometric identification,with excellent performance and stability.GZY-230

GZY-230

GZY-3100

GZY-3100

GZY-A6

GZY-A6

Product Number

Product NumberGZY-T509

GZY-T509

RFID ultra-high frequency 9dBi antenna, with strong anti-aging and weather resistance, capable of stable operation in harsh environments.

GZY-T5050

GZY-T5050

GZY-T1010

GZY-T1010

GZY-T2020

GZY-T2020

GZY-T0505A

GZY-T0505A

GZY-T0303A

GZY-T0303A

GZY-T0808A

GZY-T0808A

GZY-T0909

GZY-T0909

GZY-T1111

GZY-T1111

GZY-T506

GZY-T506

GZY-T50

GZY-T50

GZY-T512

GZY-T512

RFID 12dBi identification antenna, made of aluminum-plastic composite material with anti-aging and weather-resistant properties, suitable for logistics/asset management and other scenarios. Product NumberProduct Number

Product NumberProduct NumberRFID Reader Modules

RFID Integrated devices

Product NumberProduct Number -

Application Solutions

- Warehouse Asset Management

- Tool and Equipment Management

- Smart Port Terminal

- Personnel Location Management

- Industry manufacture 4.0

- Smart Cleaning of Linens

- Clothing retail management

Tool and Equipment ManagementPersonnel Location ManagementIndustry manufacture 4.0Smart Cleaning of LinensClothing retail management -

Successful Cases

- Intelligence Port

- Warehouse Asset

- Production Line

- Smart garbage truck

- Tool Tracking

- Personnel management

Intelligence PortWarehouse AssetProduction LineSmart garbage truckTool TrackingPersonnel management - About Infowise

- Support

- Contact Us